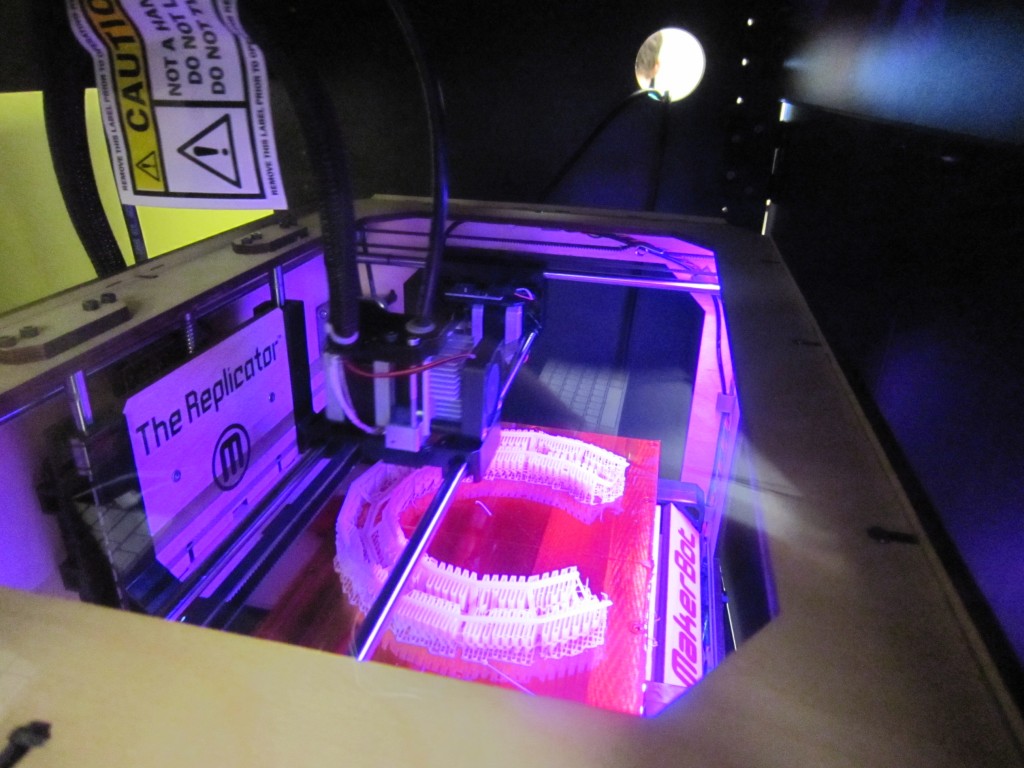

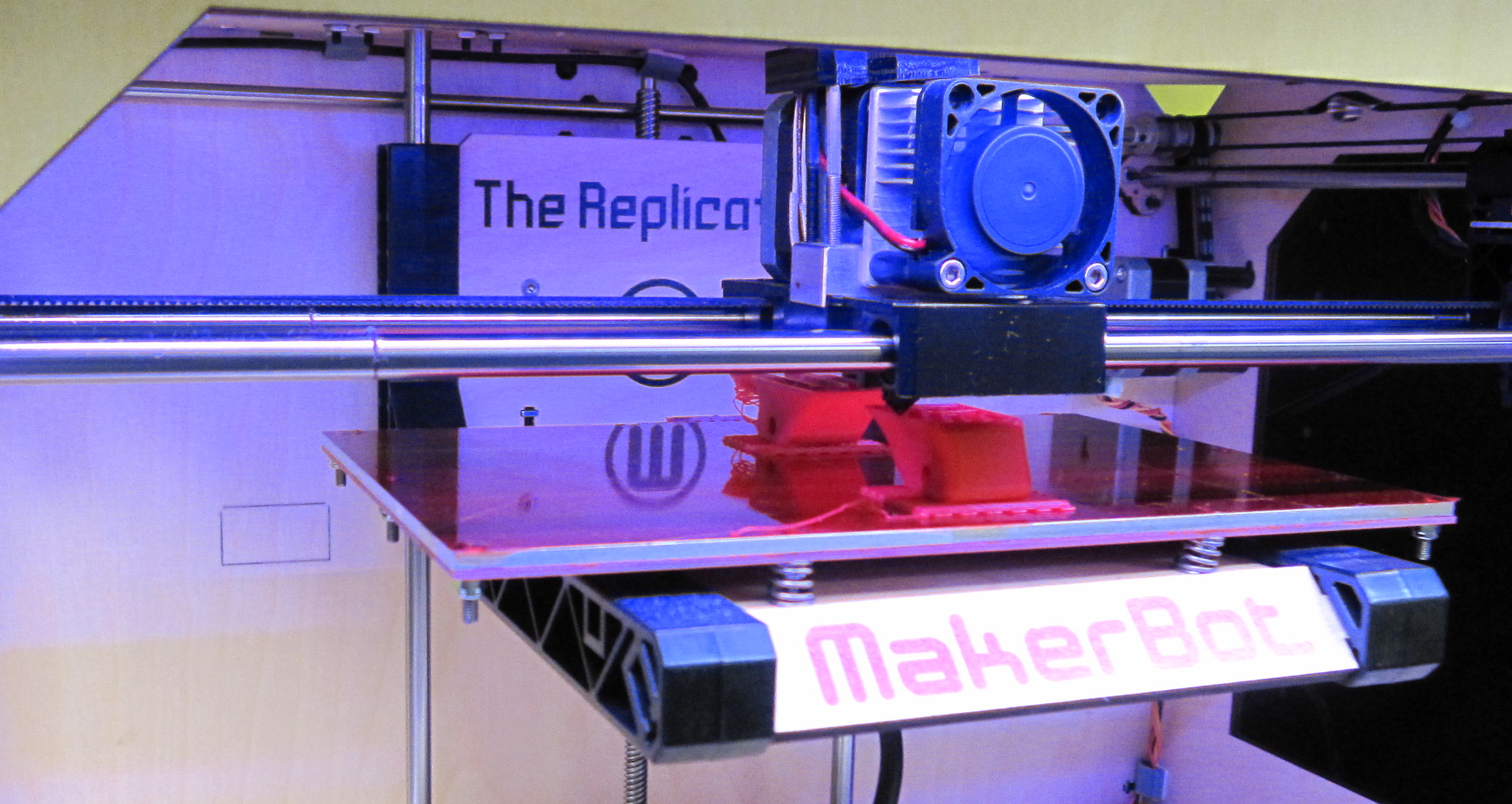

With 3D printers the sky is the limit. This incredible technology has been used to help engineers create prototype products, doctors can create plastic bones and DIY-ers around the world create tons of cool and useful gadgets. Even at Dickinson, using the Media Center’s own Makerbot printer, professors from the Mathematics and Earth Sciences departments have created 3D models to enhance their lessons.

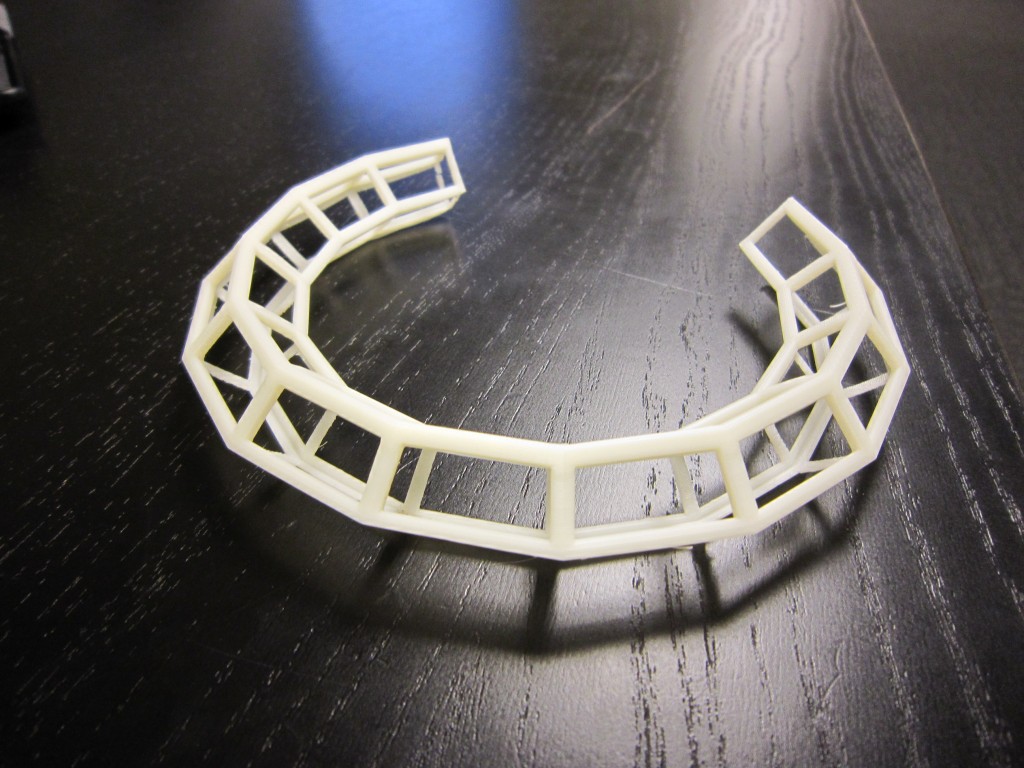

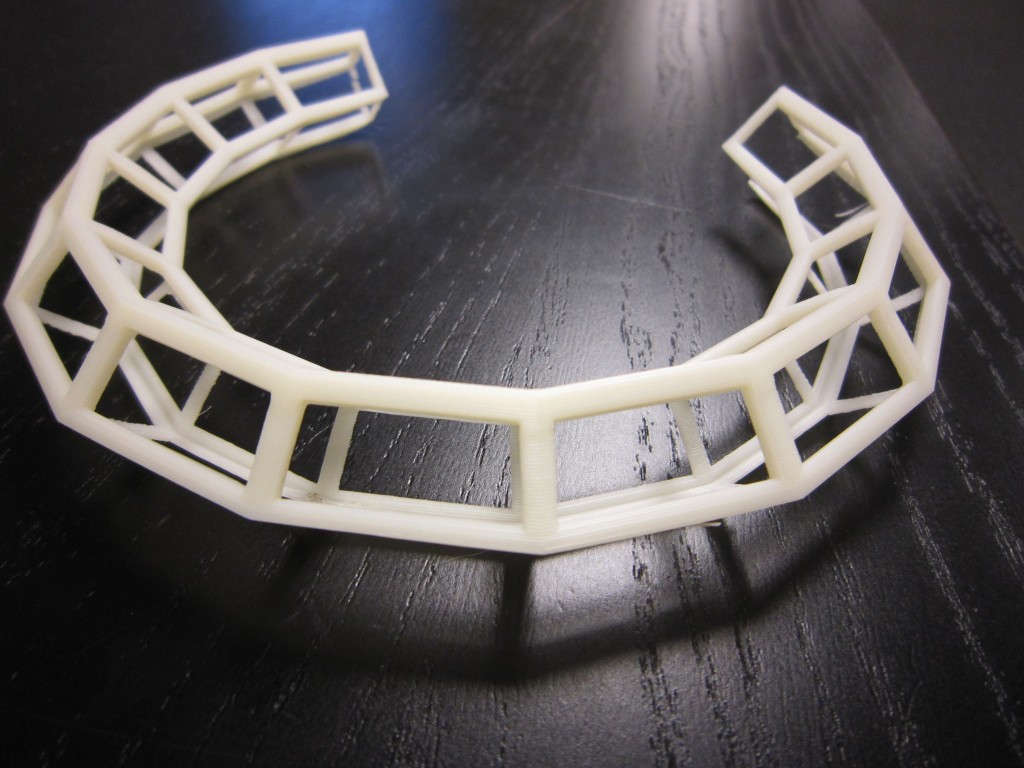

One Dickinson student has explored using the technology for something entirely different, fashion. She created a very unique necklace using a template found online on one of the countless forums where people share their designs. The use of 3D printing is a hot new trend in the fashion industry with many designers looking to dream up and print wildly intricate and imaginative works. As the printers continue to become more advance and able to print with different materials their uses will become even more widespread. Just about any industry could benefit from the ability to customize and relative ease that 3D printers offer for turning virtual creations into something physical. The possibilities are endless and the Media Center has the tools that you need to create something awesome!

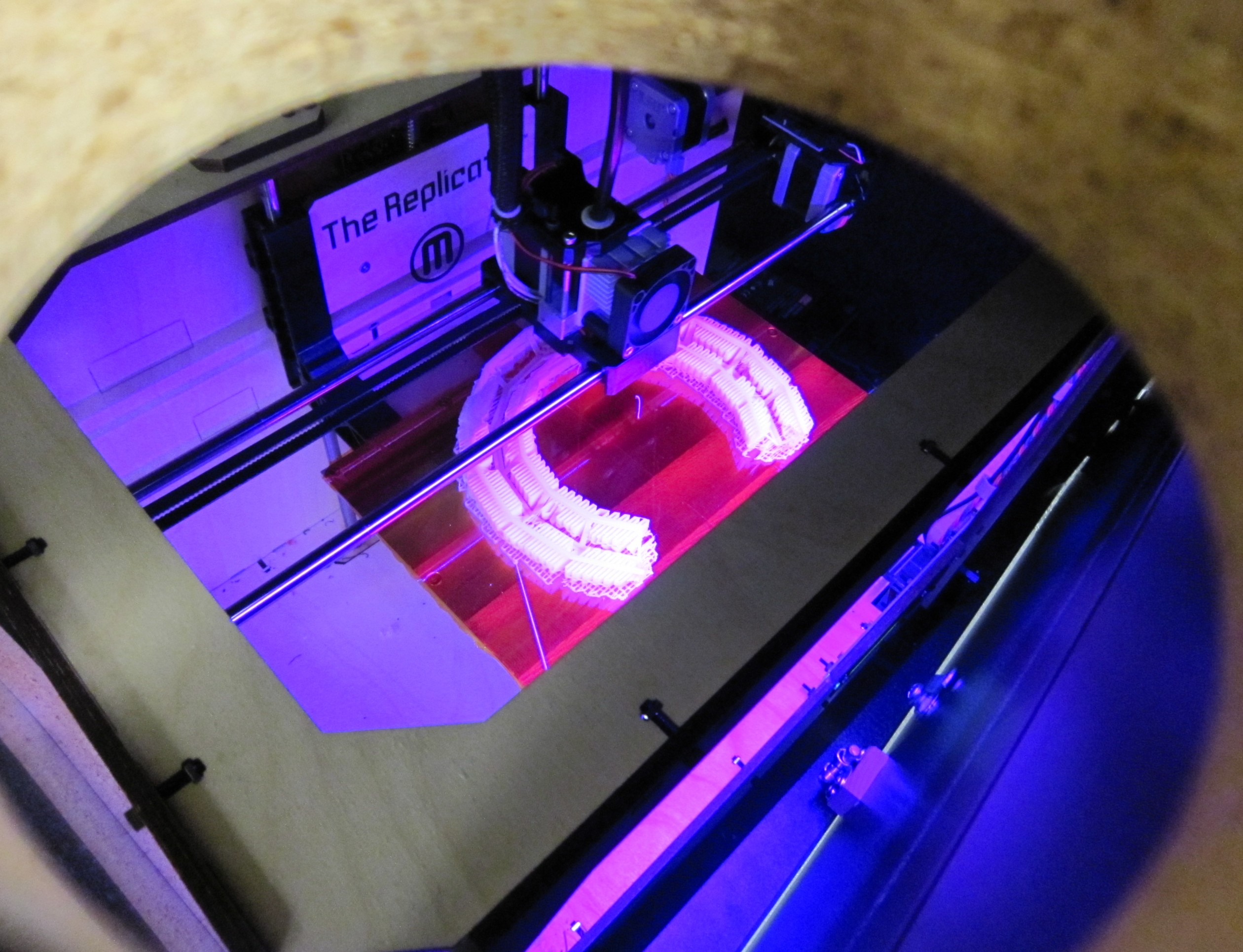

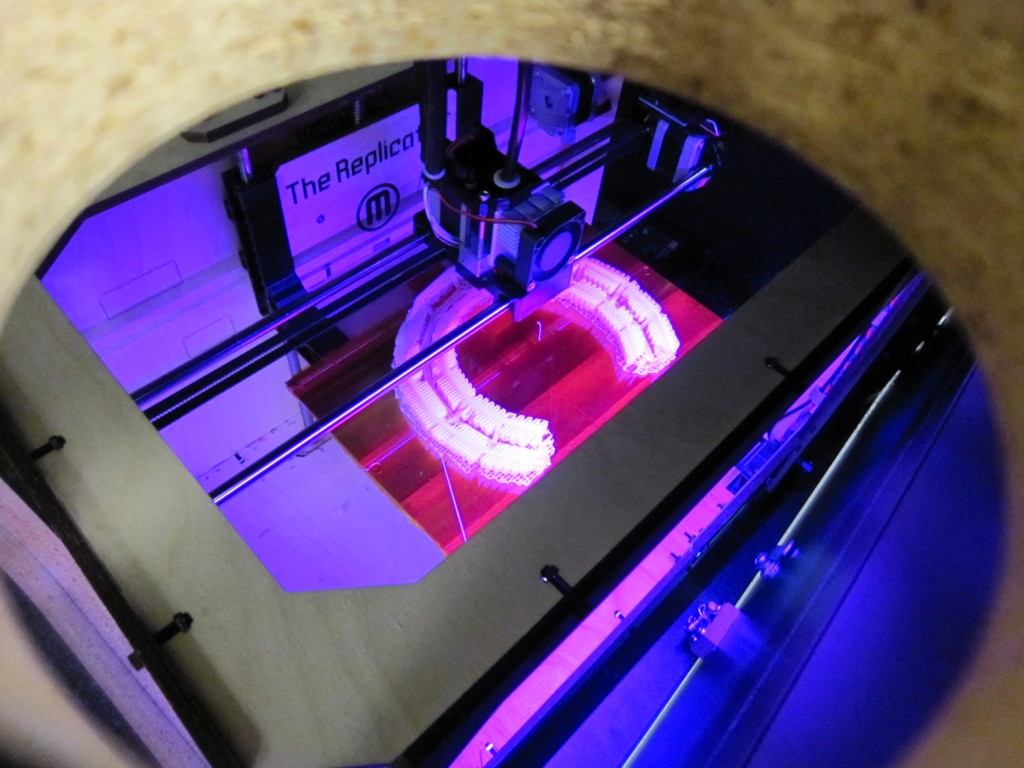

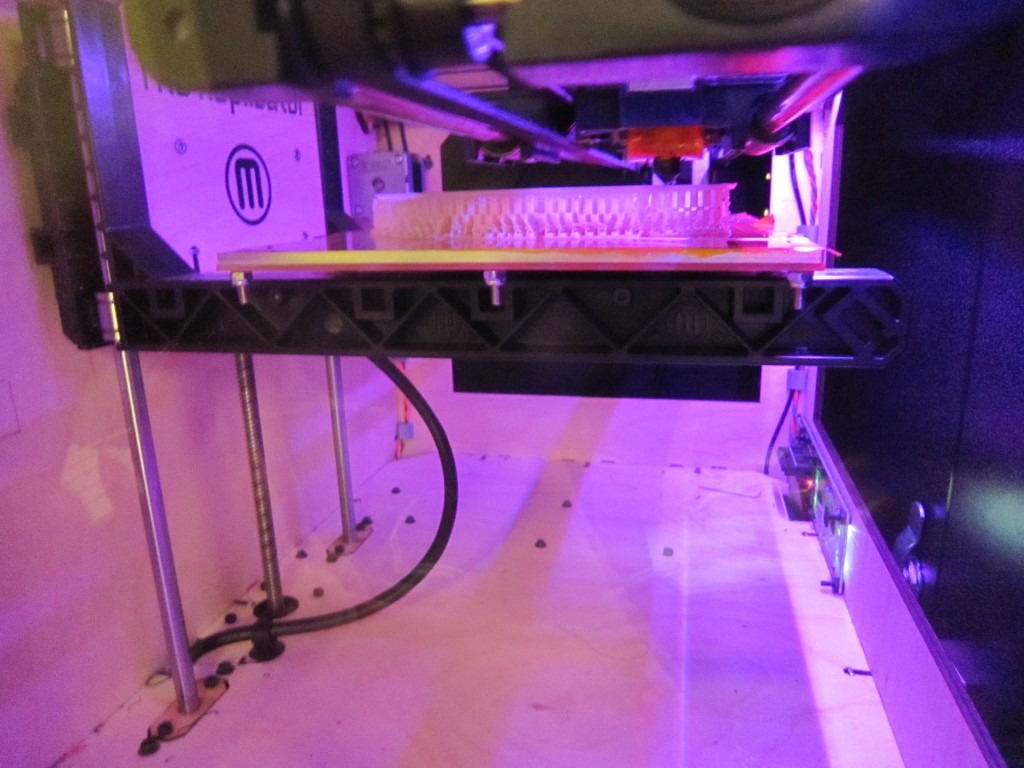

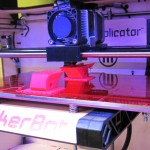

Various images from the production of the necklace