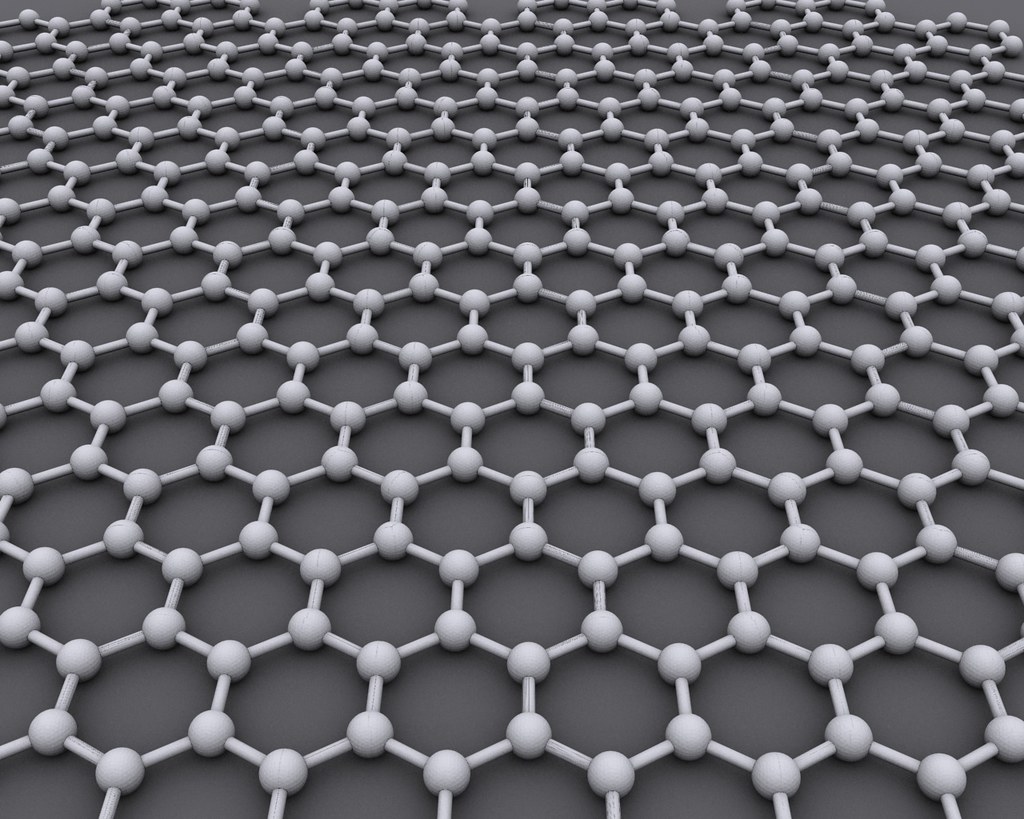

Graphene is the material of an alchemist’s dreams. The seemingly weak graphite found in a pencil is transformed into the strongest material known to mankind, albeit through a roundabout process. And while the latest method of graphene synthesis proposed by nano-chemists and nano-engineers from Rice University certainly adheres to this roundabout method, they have added a new player to the field of sustainable nanochemistry.

Trash.

No, you didn’t misread that, nor did I mistype.

Image courtesy of Creative Commons

From the hairs on our heads to our morning coffee grounds, Duy X. Long and his skilled team of researchers have devised a way to extract graphene from carbon-based trash. Through a method referred to as Flash Joule, inexpensive carbon sources – such as coal, food waste, car tires, and plastics – are shot with a high voltage, heating the material upwards of 3,000K (approximately 4,940 degrees Fahrenheit) in 0.01 seconds. This process allows tiny particles of graphene to properly align in a sturdy conformation. The speedy nature of this synthesis gave rise to the name Flash Graphene.

“…one gram of graphene can be made in 0.01 seconds…”

Once produced, Flash Graphene’s strength is applicable to a wide variety of inventions. When combined with cement, Flash Graphene disperses throughout the structure and increases its durability by ~25%. This is not only a significant improvement to the cement itself, but to different types of graphene as a whole. Flash Graphene’s ability to evenly spread throughout a product makes it a better candidate for building materials than electrochemically produced graphene. Flash Graphene’s certainly no slacker in the electronic department either. While not as powerful as other forms of graphene (such as those synthesized through electrochemical methods), renewable Flash Graphene has proven to be a strong electrical conductor suitable for building batteries.

On top of being a sustainable resource, Flash Graphene is also relatively easy and cost-effective to produce when compared to other iterations of graphene. Ordinarily, to produce graphene in bulk quantities a top-down method is utilized. This approach “exfoliates” graphite to its bare essentials through a very intensive, harsh, and chemical-heavy process. Due to the necessary materials needed to access a small amount of graphene, the synthesis results in an excess of waste. On the other hand, a traditional bottom-up synthesis, while more sustainable, ultimately yields very little product.

Flash Graphene offers another option. Unlike the top-down approach, Flash Graphene doesn’t require solvents and therefore doesn’t generate much waste. In comparison to the classic bottom-up process, the Flash Joule bottom-up method is also practical in terms of return product: one gram of graphene can be made in 0.01 seconds. The process is also simple enough that it could be automated for continuous synthesis in an industrial setting. Combined, these improvements imply that we could very well see Flash Graphene implemented in our everyday lives in the future.

https://www.nature.com/articles/s41586-020-1938-0

Luong, D.X., Bets, K.V., Algozeeb, W.A. et al. Gram-scale bottom-up flash graphene synthesis. Nature 577, 647–651 (2020). https://doi.org/10.1038/s41586-020-1938-0

murphymv

Awesome article! I like the personality in the writing. Flash Graphene not only sounds cool, but is also very efficient and practical. I hope it is used and researched more moving forward.